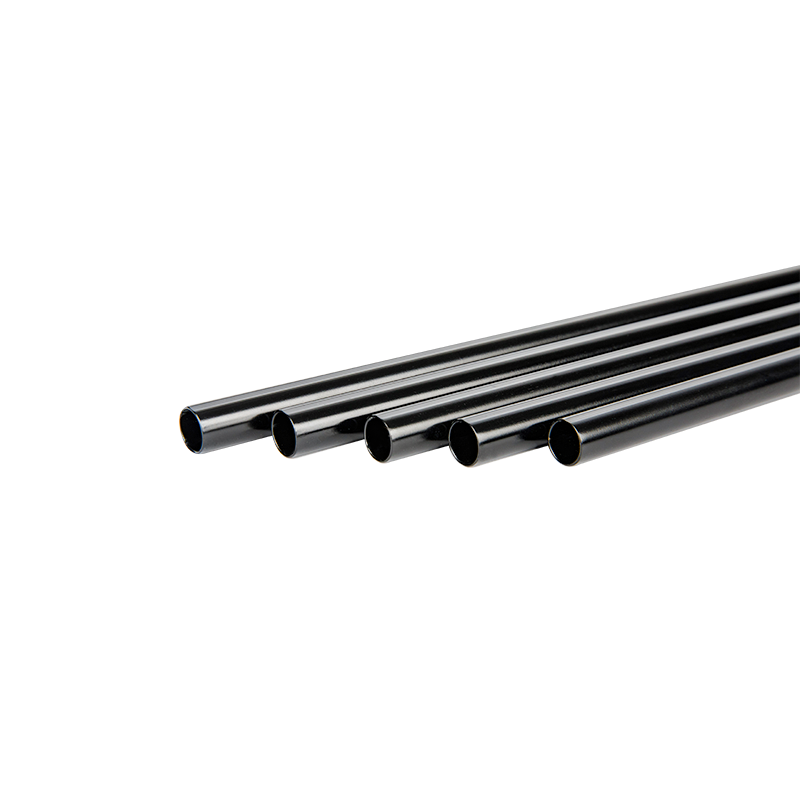

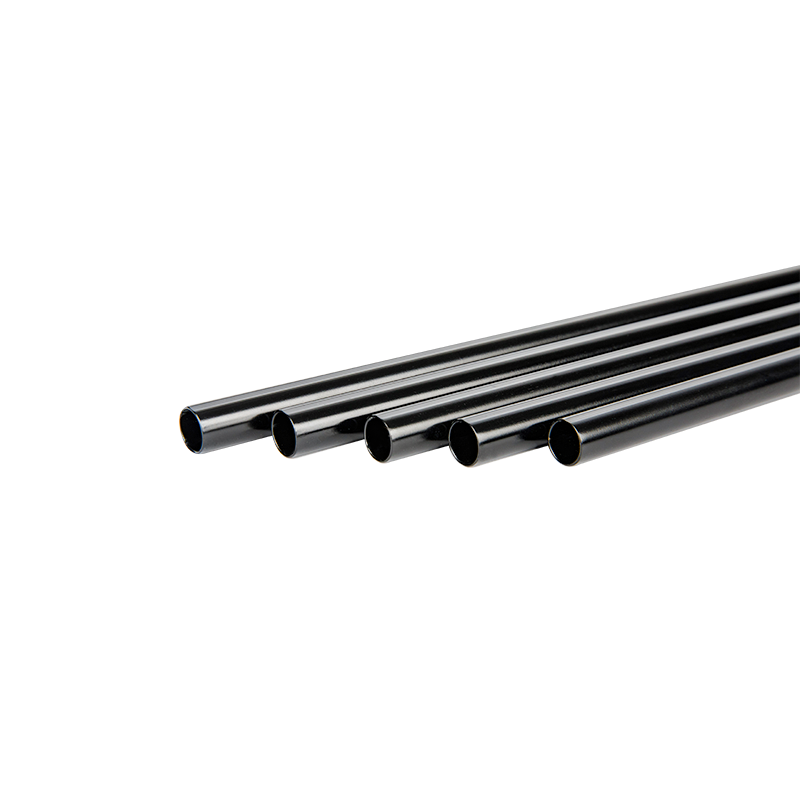

The world of HVAC and plumbing has witnessed numerous advancements and innovations over the years. One such innovation is the outer diameter grooved tube, which has proven to be a game-changer in the industry. The grooved tube technology has revolutionized the way pipes are joined together, making it easier, quicker, and more efficient.

Outer diameter grooved tube is a type of pipe that features a groove on its outer surface. The groove is created using a special tool that cuts a precise groove into the pipe. The groove is then filled with a rubber gasket, which acts as a sealant and holds the pipe in place. The result is a pipe joint that is strong, leak-free, and easy to install.

The advantages of using

outer diameter grooved tube are many. Firstly, it eliminates the need for welding, threading, or flanging, which are traditional methods of pipe joining. These methods are time-consuming, labor-intensive, and require specialized equipment. Grooved tube technology, on the other hand, requires only a grooving tool, a rubber gasket, and a few basic tools, making it much simpler and faster.

Secondly, grooved tube technology allows for greater flexibility in piping systems. The grooved pipe can be easily adjusted or reconfigured to meet changing requirements or to accommodate future expansions. This makes it ideal for use in buildings where space is limited, or where the piping system needs to be modified frequently.

Another advantage of grooved tube technology is that it provides a stronger joint than traditional methods. The rubber gasket used in the groove creates a tight seal that prevents leaks, even in high-pressure applications. Additionally, the groove provides a mechanical lock that ensures the pipe will not separate or slip out of place under stress or vibration.

The use of outer diameter grooved tube has become increasingly popular in the HVAC and plumbing industry, especially in large-scale commercial and industrial projects. It is commonly used in chilled water systems, heating systems, and fire protection systems. The technology has also been adopted in the mining, oil, and gas industries, where it is used for fluid and gas transport.

In conclusion, the outer diameter grooved tube is a revolutionary technology that has transformed the way pipes are joined together. It offers numerous advantages over traditional methods of pipe joining, including greater speed, flexibility, and strength. The technology has become an essential tool in the HVAC and plumbing industry, enabling faster and more efficient installation of piping systems.